E-methane production

Since 2022, GRTgaz has been using the Jupiter 1000 demonstrator to experiment with the production of e-methane – a synthetic gas produced from renewable hydrogen and recycled CO2 – with a view to injecting it into the gas transmission system. The aim is to significantly reduce the emission of carbon into the atmosphere.

Understanding e-methane production

How does Power to Methane work?

E-methane is a synthetic gas produced from renewable hydrogen and recycled CO2. It is produced in two stages:

- Green hydrogen is produced from renewable electricity using electrolysis technology, based on the Power to Hydrogen principle.

- Anaerobic digestion itself takes place, i.e. the reaction of renewable hydrogen with recycled CO2 in the presence of a catalyst.

These two stages, when implemented together, constitute Power to Methane.

What are the advantages of e-methane?

E-methane holds great promise for the decarbonisation of energy uses. On the one hand, it converts non-storable electricity into storable renewable gas. On the other, it recovers the CO2 released by industrial sites or extracted from the biogas during the purification phase of biogas production, pyrogasification or Hydrothermal Gasification (processes for producing renewable gases from biomass, solid waste or liquid or wet waste, respectively).

Thanks to e-methane, the CO2 released is given a new lease of life, helping to reduce the global carbon footprint.

E-methane can be stored and injected directly into the GRTgaz transmission system, without requiring any prior adaptation of the infrastructure. As a substitute for natural gas, it covers domestic and industrial uses (heating, electricity). It can be used in road (bioGNV) and sea transport.

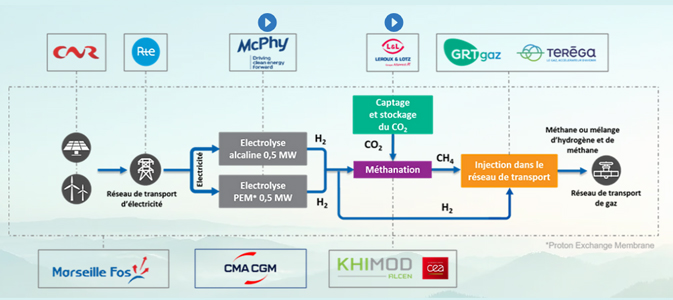

Jupiter 1000, an innovative project involving a Power to Gas and anaerobic digestion industrial demonstrator

GRTgaz and its partners have been developing the Jupiter 1000 industrial demonstrator project. Located in Fos-sur-Mer in France’s Bouches-du-Rhône region, this innovative project has two objectives: to validate the operation of Power to Gas (Power to Hydrogen and Power to Methane) and to illustrate the benefits of linking electricity and gas networks. This is France’s first project on a megawatt scale. It combines the production of renewable hydrogen, the injection of e-methane and renewable hydrogen into the gas transmission network, and the recovery of recycled CO2.

The project reached its first milestone in 2020 with the conversion of local wind-generated electricity into renewable hydrogen for injection into the gas transmission network. The site is equipped with electrolysers, which have a total capacity of 1 MWe, to produce renewable hydrogen.

Since July 2022, the anaerobic digestion reactor has been testing the production of e-methane from recycled CO2 and renewable hydrogen. It uses CO2 captured from the fumes emitted by Asco Industries – a nearby steelworks.

GRTgaz is supporting this project with a number of partners: the anaerobic digestion reactor was built by Khimod with the support of the French Alternative Energies and Atomic Energy Commission (CEA), the CO2 capture facility was created by Leroux & Lotz Technologies, and the pipeline for transporting the CO2 to Jupiter 1000 was built by the Grand Port Maritime de Marseille.

Source: https://www.jupiter1000.eu/projet

The Jupiter 1000 project is co-financed by the European Union as part of the ERDF Fund, the French government as part of the “Investissements d'Avenir” programme managed by ADEME, and the Provence-Alpes-Côte-d'Azur Region.

The Commission for Energy Regulation (CRE) also supports the Jupiter 1000 project which plays a role in the energy transition, and aims to diversify the uses of natural gas networks in the long term.