PLAINÉNERGIE: transforming our residual waste into renewable gas

This is the first project in Europe combining pyro-gasification and biological methanation to transform non-recovered waste into renewable gas, which can ultimately be injected into the existing gas network. This innovative project is central to the challenges of the energy transition and the circular economy.

An innovative project that is central to the circular economy and the energy transition

PLAINÉNERGIE aims to develop a first experimental industrial facility for the treatment and energy conversion of a wide range of residual waste collected from the Community of Municipalities of the Plaine de l'Ain (CCPA) and the Plaine de l’Ain Industrial Zone (PIPA) and not recovered elsewhere1. The aim is to produce renewable gas that can eventually be injected into the existing gas network.

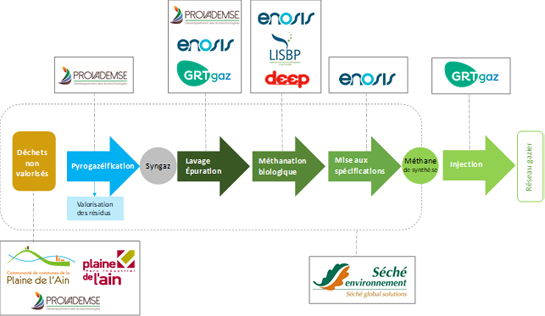

This project combines two key waste recovery technologies: pyro-gasification combined, for the first time, with a biological methanation process - an innovative technology. Pyro-gasification covers various specifically adapted technologies. It is particularly effective for the energy conversion of waste that could not be recycled. It allows the material to be broken down into different molecules and form a syngas2. Through a biological methanation process, this syngas can then be converted into synthetic methane, which can be substituted for natural gas in all of its uses (residential, industrial, fuel).

A four-phase project

The initial laboratory phase is already underway. Its aim is to characterise waste deposits and to adapt and optimise the pyro-gasification and biological methanation processes. Next, PLAINÉNERGIE plans a preliminary test phase using pilot equipment on the PROVADEMSE technological platform that simulates an industrial environment. Third, extensive testing must be followed with the implementation of a pre-industrial pilot facility.

Finally, in view of the performance observed for this facility, PLAINÉNERGIE could give rise to the construction of an experimental industrial unit located in the Plaine de l’Ain Industrial Zone. The unit would be designed using a short supply chain and could be duplicated in other territories. A facility such as this would thus contribute to the development of the pyro-gasification sector for the purpose of injecting locally produced gas into the networks, with a view to decarbonising the energy mix. According to the French Environment and Energy Management Agency (ADEME), France could produce more than 100 TWh of gas per year by pyro-gasification by 20503 - around one-third of the national gas mix.

An PPP association involving sector representatives

INSAVALOR's technological platform, PROVADEMSE, specialises in developing of innovative eco-technologies. It coordinates the project and makes available its equipment and waste characterisation and recovery known-how, in particular relating to pyro-gasification. The CCPA and the SMPIPA are responsible for identifying and processing waste deposits.

In partnership with the Laboratory for the Engineering of Biological Systems and Processes (LISBP) at INSA Toulouse and the Laboratory for Waste, Water, the Environment and Pollution (DEEP) at INSA Lyon, ENOSIS develops and optimises biological methanation technology, adapted to syngas processing.

The industrial group Séché Environnement provides its expertise in process integration and operating waste recovery centres. GRTgaz, a gas transmission network operator, provides its know-how in injecting and controlling the composition of the gases injected into the networks.

1 End-of-life wood, plastic waste, bulky waste from landfills, agricultural residues, waste from economic activities, other non-recyclable and non-methanisable waste, etc.

2 Syngas is a gas composed mainly of hydrogen (H2), carbon oxide (CO), carbon dioxide (CO2), and methane (CH4).

3 Source: ADEME study, “A 100% renewable gas mix in 2050” (January 2018).