Renewable and low-carbon gases

GRTgaz is actively committed to developing renewable and low-carbon gases in line with French and European policy aimed at achieving carbon neutrality by 2050. On the one hand, GRTgaz is adapting its industrial facilities to encourage the injection of renewable gases into its transmission network; and, on the other, it supports the growth of innovative renewable and low-carbon gas production sectors.

Renewable and low-carbon gases: core components of the 21st century energy mix

Gas is a core component of the future energy mix. The challenge lies in gradually replacing fossil natural gas with a sustainable energy solution: renewable and low-carbon gases.

Renewable and low-carbon gases enable waste to be recovered as part of a virtuous circular economy, creating local jobs that are not at risk of relocation.

They contribute to decarbonising all gas uses, particularly in industry and transport.

“Waste-to-energy, the circular economy, energy autonomy, GHG reduction: renewable and low-carbon gases combine all of these benefits. GRTgaz believes strongly in their energy, environmental, economic and regional potential. It is committed to integrating these renewable and low-carbon energies into the energy mix of tomorrow for a safe, sustainable future.”

Anne Évrard, Renewable Gas and Hydrogen Project Manager

Waste recovery

Various production techniques allow waste to become a virtuous resource for reducing our ecological footprint. Producing renewable, low-carbon gas from waste avoids incineration and landfill, as well as reducing negative environmental impacts.

Renewable gas production technologies recover residues from multiple sources, including agriculture, the food processing industry, mass catering, household waste or green waste collection, wood waste collection, water treatment plants, non-hazardous waste storage facilities, non-recyclable waste, solid recovered fuels, etc.

Cultivating a circular economy in the regions

Renewable and low-carbon gases contribute to the emergence of a circular economy that aims to limit waste and create local value by recycling previously used material. For example, agriculture provides recoverable inputs, then takes the digestate generated by the renewable gas manufacturing process and uses it as fertilizer.

Supporting energy autonomy

Renewable and low-carbon gases are locally produced energy sources that contribute to France’s energy sovereignty. They offer a way to reduce fossil gas imports. Finally, they contribute to achieving the European goal of diversifying energy supplies under the REPowerEU plan.

Further reading: We are breaking our dependence on fossil fuels

Virtuous and diversified sectors

To promote the production and consumption of cleaner energy, GRTgaz supports the accelerated growth and structuring of four renewable and low-carbon gas production sectors: anaerobic digestion, pyrogasification, la hydrothermal gasification and the production of e-methane by methanation.

Further reading: We are developing the technologies of the future

Renewable gases:

diversified sectors

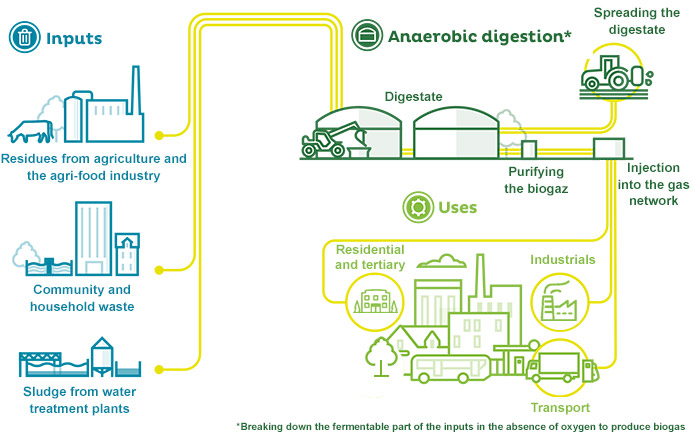

Anaerobic digestion involves processing organic materials from various sectors including agriculture, manufacturing, catering waste, community waste, etc. Fermenting this material in the absence of oxygen produces biogas, which, once purified, becomes biomethane.

Anaerobic digestion is a virtuous local circular economy model. While farmland provides the raw material for renewable and low-carbon gas production, it also benefits from the anaerobic digestion process, which creates residues – digestates – that are effective organic crop fertilizers.

Anaerobic digestion is now a mature industry. Its annual production capacity connected to the networks has doubled in the past two years. With 674 injection sites in the French natural gas distribution and transmission network at the end of March 2024, biomethane is playing its part in decarbonising the French energy system. In March 2024, these represented a production capacity of 12.1 TWh/year for renewable and local gas, i.e. approximately 2% of French gas consumption. Of these, 84 biomethane production sites are connected to the GRTgaz network.

GRTgaz also builds reverse flow facilities to direct excess biomethane from the distribution network to the transmission network, for transportation to more remote consumption areas.

From anaerobic digestion to injection: key steps

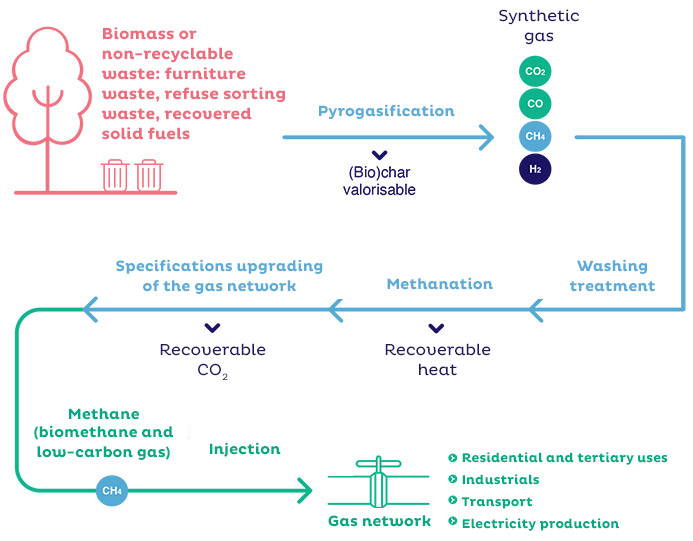

Pyrogasification transforms dry solid waste that is poorly recovered or non-recovered (biomass residues, wood and furniture waste, solid recovered fuels, etc.) into renewable and low-carbon gas. When heated at very high temperatures (800-1500°C) with little or no oxygen, then processed, these produce a methane-rich gas that can be injected directly into the networks.

This innovative sector is entering the industrialisation phase. In 2022, GRTgaz supported the Call for Expressions of Interest launched by the sector strategy committee (CSF), New Energy Systems . Forty-nine projects are currently identified, with a production potential of 4.1 TWh/year. The goal is to deploy the first industrial and commercial projects in 2026-2027.

Pyrogasification for injection into the networks

“Pyrogasification harnesses inputs that cannot be recovered by the other waste-to-gas processing sectors. With high levels of complementarity to other technologies, it has strong potential in the field of renewable and low-carbon gas production. It also offers a promising alternative for the local management of poorly recovered or non-recovered solid waste, which formerly could only be buried or incinerated.”

Clotilde Villermaux, Pyrogasification Project Manager.

Pyrogasification for the injection of gas into the networks

“Pyrogasification harnesses inputs that cannot be recovered by the other waste-to-gas processing sectors. With high levels of complementarity to other technologies, it has strong potential in the field of renewable and low-carbon gas production. It also offers a promising alternative for the local management of poorly recovered or non-recovered solid waste, which formerly could only be buried or incinerated.”

Clotilde Villermaux, Pyrogasification Project Manager.

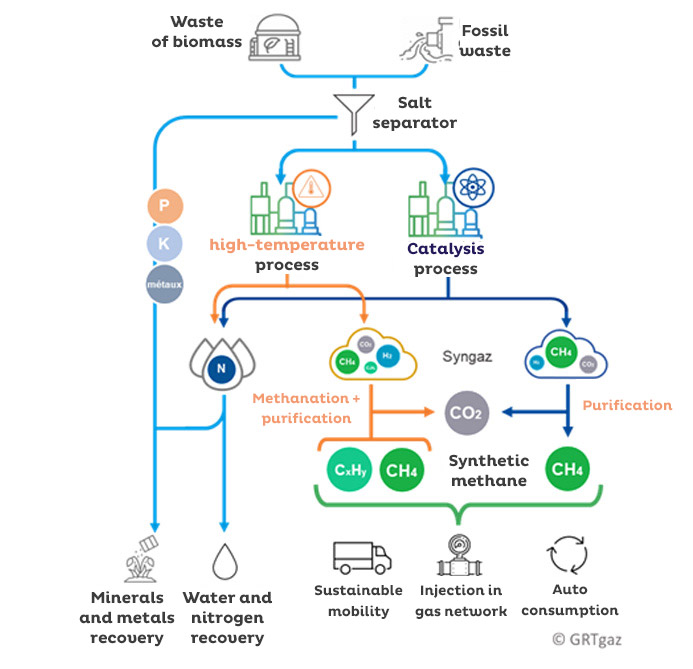

Hydrothermal Gasification produces a renewable gas rich in methane and hydrogen by heating wet or dry biomass effluents and liquid organic waste at high pressure (200-300 bars) and high temperature (400-700°C).

The process offers a renewable gas conversion solution for a wide range of urban and suburban businesses, as well as local authorities and even waste processing operators.

In 2023, a White Paper was published by the Hydrothermal Gasification Working Group led by GRTgaz and involving 27 partners. This report sets out the sector’s current situation and potential. It proposes strategic guidelines to establish the economic, technical and environmental conditions needed to develop Hydrothermal Gasification in France. Plans are in place to build the first industrial Hydrothermal Gasification facilities by 2026-2027.

“Hydrothermal Gasification is a highly innovative and efficient technology that recovers a very wide range of organic waste as renewable and low-carbon gas. Its global energy recovery minimises - or even reduces - the quantity of final waste and air pollutants. It forms part of the regions’ circular economies, short supply channels and decarbonisation efforts.”

Robert Muhlke, Head of Hydrothermal Gasification

The Hydrothermal Gasification process

White Paper Hydrothermal Gasification

Methanation is an emerging gas production technology. It consists of producing synthetic methane, or e-methane, by combining hydrogen from electrolysis (Power to Gas) and CO2 from biogas purification or industrial processes. The e-methane generated by this combination of hydrogen and CO2 can be injected directly into the networks and stored in the gas infrastructures.

GRTgaz has developed the Jupiter1000 demonstrator to confirm the workings of this technology for producing e-methane via methanation, and to show the benefits of harmonisation between the electricity and gas networks.

Developing renewable gases: working together to become more efficient

GRTgaz is one of France’s major gas stakeholders. For several years, it has been expanding its cooperation with technical sectors, local authorities and industrials (waste producers, equipment manufacturers, integrators, project developers...) to support the emergence of energy solutions and sustainable decarbonisation.

Alongside its partners (the Syndicat des Énergies Renouvelables, the association France Gaz and France Gaz Renouvelables, the Association des Agriculteurs Methaniseurs de France, etc.), GRTgaz supports the introduction of a legislative and economic framework that promotes the co-construction of local solutions for the production and consumption of renewable and low-carbon gases.

Through its support for Calls for Expressions of Interest (CEI)*, GRTgaz intends to show the potential of innovative production and injection channels for renewable and low-carbon gas, as well as producers’ and consumers’ strong interest in these decarbonisation solutions.

GRTgaz informs, advises and supports the emergence of tangible projects as part of national and regional collectives. The company participates in numerous working groups that bring together stakeholders in the renewable and low-carbon gas value chain. The aim is to bolster sector structuring, promote discussion, produce technical and economic studies, and make proposals to the public authorities (Pyrogasification Club within the French Technical Energy and Environment Association (ATEE); national working group on hydrothermal gasification; CORBI anaerobic digestion collective in the Hauts-de-France region, etc.).

“Efforts to develop renewable and low-carbon gases require action at three levels: production, injection into the network, and consumption. GRTgaz’s commitment extends throughout the value chain by supporting the development of innovative and sustainable production sectors, adapting its industrial infrastructure, and encouraging the dissemination of decarbonised uses in mobility and industry.”

Jean-Marc LE GALL, Head of the Gas Development Division.

*A Call for Expressions of Interest (CEI) is a procedure used to identify economic operators likely to propose a solution that meets an existing need, and to initiate a technical dialogue with them or simply source the available solutions.

Supporting the development of low-carbon uses

Renewable and low-carbon gases are a pragmatic, accessible solution for decarbonising all gas uses, particularly in industry and mobility.

Decarbonising industry

Renewable gas is taking over from fossil fuels in industrial production processes. Chemicals, refining, electronics and food production are supplied with renewable gas for use in their processes (raw materials, heat production, electricity production).

GRTgaz carries out regulatory monitoring to support manufacturers and encourage them to integrate renewable gases into their decarbonisation strategy. The transition does not require any changes to be made to the existing gas facilities.

Decarbonising transport and (bio)NGV

When it comes to mobility, GRTgaz is developing the fuelling network for vehicles using NGV – a fuel that contributes to reducing GHGs (- 25% and -10% of CO2 compared with petrol and diesel, respectively). BioNGV from biomethane is 100% renewable.

By allowing economically viable stations to connect to the transmission network, the French Mobilities Framework Law (Loi d’Orientation des Mobilités, or LOM) enables new projects to connect to the GRTgaz network. At end-December 2022, 288 bioNGV fuelling sites were connected in France. Renewable gases have also emerged as an alternative for marine fuel.

Publications