Low-carbon hydrogen: the DHUNE project takes a decisive step forward in Dunkirk

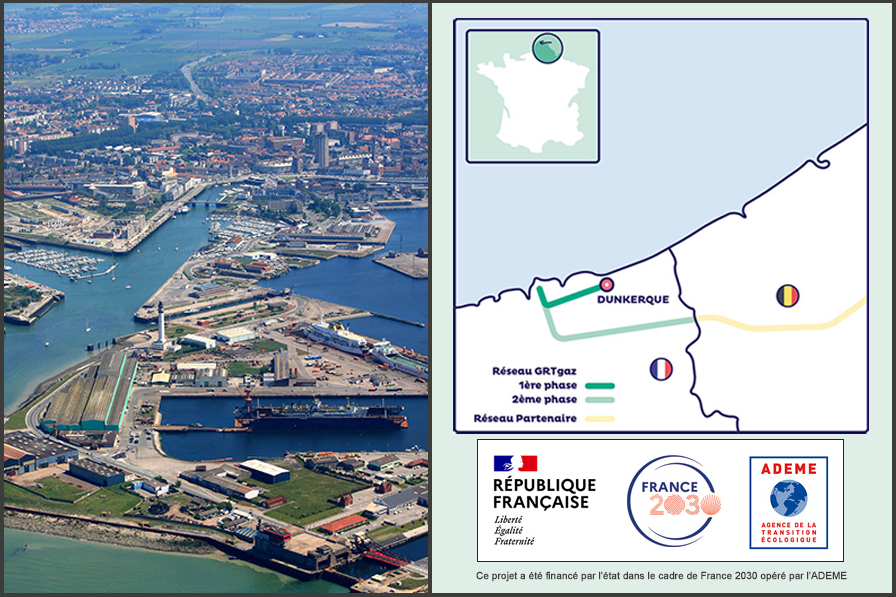

In January 2024, basic engineering studies for the DHUNE H2 transportation project began in Dunkirk. These studies are essential before construction can begin on the future hydrogen transport infrastructure within the industrial port zone.

The DHUNE (Dunkirk Hydrogen Universal Network) project has entered its third phase of development. Following the success of the call for expressions of interest and the completion, in 2023, of the first feasibility studies, co-financed by the French government as part of the France 2030 programme run by ADEME, GRTgaz launched a basic engineering or FEED (Front End Engineering Design) study in January. This study, which is much more in-depth than the previous one, will last 18 months and will lead to an “initial complete engineering design” explains Marion Lacombe, Business Developer in GRTgaz’s Development Department.

In concrete terms, this study will analyse and clarify all aspects of the project, from the projected route to the technical, land, administrative, environmental and industrial safety issues. “We’re getting to the heart of the matter. Building a hydrogen transport infrastructure in such an industrial port area is complex, particularly in terms of land or watercourse crossings,” explains Marion Lacombe.

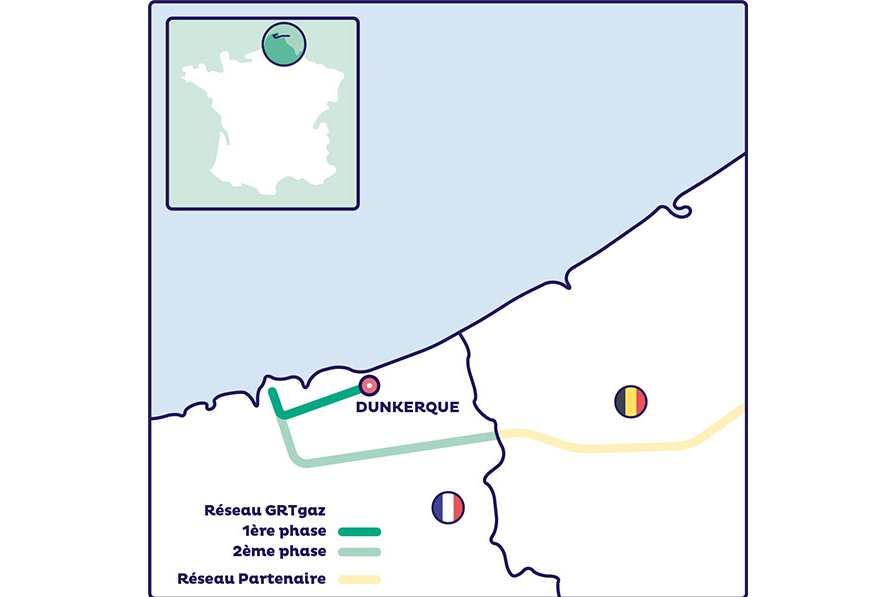

This study is also a prerequisite for GRTgaz’s Final Investment Decision (FID), which could be made before the end of 2025. Lastly, it is a key element in the submission of applications to obtain the administrative authorisation to build and operate the infrastructure. The first 10-km section of the transport system, operated by GRTgaz, is scheduled for the end of 2027.

Dunkirk, a priority area for industrial decarbonisation

The area accounts for no less than 20% of all industrial CO2 emissions in France. “It has become one of the major basins to be decarbonised. Alongside manufacturers, the Grand Port Maritime de Dunkerque and the Urban Community of Dunkirk (CUD) are very committed to making this transition a success,” explains Marion Lacombe. Low-carbon hydrogen has been identified as one of the levers for decarbonisation in an ecosystem characterised by the presence of numerous energy production sites (nuclear power station, LNG terminal, thermal power station, etc.) as well as metallurgical and petrochemical production sites, including the ArcelorMittal steelworks. The steel group is one of GRTgaz’s top three industrial customers actively involved in the DHUNE project, along with Imerys and the hydrogen producer, H2V. The company has been “involved in the Dunkirk area since 2018,” explains Alexis Martinez, Managing Director. “We have all the necessary permits to implement our green hydrogen gigafactory project, which we plan to bring into service at the end of 2027.”

Low-carbon hydrogen: ArcelorMittal in the lead

ArcelorMittal’s ambition is to reduce its total GHG emissions by 35% by 2030, and to become carbon neutral by 2050. However, most of its carbon footprint comes from the primary phase when the raw material is transformed into crude steel, which is currently coal-fired. “Our blast furnaces in Dunkirk emit almost 12 million tonnes of CO2 a year, with a factor of 1.8 tonnes of CO2 emitted for every tonne of steel produced,” explains Thomas Bulteau, Manager of Energy Support for ArcelorMittal France.

Aware of its responsibility, the Group has decided to “get to the heart of the problem” and is investing massively to move away from coal and towards low-carbon gas (or biomethane) and hydrogen. Low-carbon hydrogen will play an increasingly important role in this mix over time, depending on its availability in terms of production. On site, the transformation will take the form of the installation of a DRI (direct reduction of iron) unit, capable of operating on both gas and hydrogen. It will be coupled to two electric furnaces, which are essential for melting steel.

At the same time, ArcelorMittal is pulling other decarbonisation levers: steel recycling and CCCUS (Carbon Capture, Utilisation and Storage. “Whether we’re talking about natural gas, hydrogen or electricity, this transition implies major new power requirements, which will have to make their way to our site. So, it was logical for us to get involved in a shared transport infrastructure project such as DHUNE,” underlines Thomas Bulteau. “We share the same vision as GRTgaz of the network and territorial coverage.”

Phase 2 to Belgium

After 2030, the DHUNE network is set to expand. This second stage will involve interconnecting the first section in Dunkirk with neighbouring Belgium and, by extension, with the Hydrogen European Backbone. It is with this in mind that a wider Franco-Belgian hydrogen corridor project, led by GRTgaz, of which the DHUNE project is the first phase, was designated a “Project of Common Interest” by Europe in November 2023.

“That’s why we’re continuing to exchange ideas with other players in the regional ecosystem”, says Marion Lacombe. ArcelorMittal shares this open and progressive vision: “DHUNE takes its full meaning from the interconnection. Other projects will emerge around Dunkirk and in Belgium. We’ll need them and they’ll need us,” summarizes Thomas Bulteau.

This project was financed by the State as part of France 2030 operated by ADEME: