Biogas production

Biogas production, a mature and dynamic industry

Biogas production is the most mature renewable and low-carbon gas production method in France. By 2024, 652 biomethane production sites were injecting biomethane into France’s gas networks, with a total capacity in excess of 11 TWh/year – equivalent to the production capacity of two nuclear power stations. Biogas production, a virtuous, local circular economy model, is one of the most advanced solutions for driving the energy transition and decarbonisation forward.

“Biogas production is the most mature method of producing renewable and low-carbon gas. Along with the other gas system operators in France, GRTgaz is taking a proactive approach with the aim of mobilising project developers and facilitating the installation of new biogas production units. What are the objectives? To support decarbonisation and the energy autonomy of France’s regions.”Frédéric Guillou

Head of Anaerobic Digestion Development at GRTgaz

Understanding biogas production in 4 points

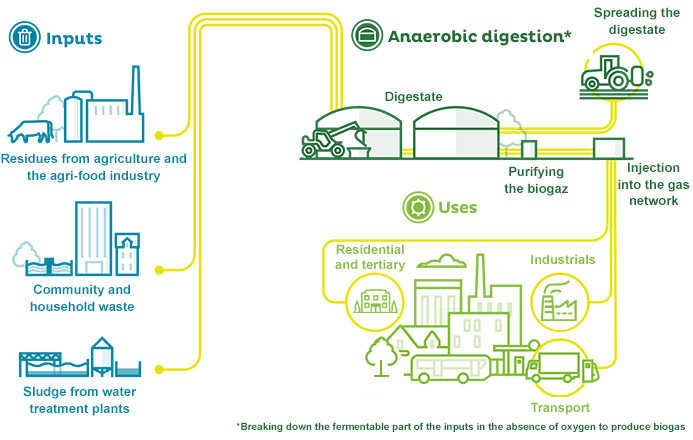

Biogas production is the process of producing renewable gas from biomass and wet, liquid and dry organic waste from a variety of sources:

- The agricultural sector: manure, cattle effluent, intermediate energy crops, chaff (broken grain, husks and glumes from cereal grain), cereal by-products (broken grain, dust, etc.), peelings, etc.

- The food industry: waste from canteens and restaurants, out-of-date foodstuffs (salad dressing, edible oil, mustard, etc.)

- Local authorities: waste from local communities and catering companies.

- Sludge from wastewater treatment plants.

The biomethane produced by anaerobic digestion can be injected directly into the gas transmission network to serve all uses, e.g. residential, tertiary, industrial and mobility.

Three stages are involved in injecting the biomethane produced from anaerobic digestion into the grid:

- Fermentation: the organic raw materials are broken down by micro-organisms in the digester, in the absence of oxygen, at a temperature of 35 to 40°C. This fermentation process produces biogas, essentially composed of methane and CO2.

- Purification: the different molecules are separated. The CO2 and sulphurous hydroxides are extracted so that the biogas reaches a methane content and energy density equivalent to that of traditional natural gas.

- Odorisation: before it is injected into the gas network, the biomethane is odorised so that potential gas leaks can be detected.

This process generates residues known as digestate. Made up of bacteria and minerals, digestate is an effective organic fertiliser that nourishes the soil and replaces chemical fertilisers.

Anaerobic digestion is a mature, high-performance process that breaks down organic waste to produce a methane-rich gas that can be injected directly into networks, replacing fossil natural gas.

Its other assets:

- Non-intermittent production of storable and available energy

- Recycling of organic waste

- Production of digestate, rich in organic and mineral components that can be used in agriculture as fertiliser

- Reduction of greenhouse gases

- A circular economy on a regional scale, creating jobs not vulnerable to relocation

- Stable supplementary income for farmers.

Anaerobic digestion is being developed according to a virtuous local circular economy model, bringing together local authorities, farmers, waste producers and private industrial consumers. It contributes to energy sovereignty and the decarbonisation of territories.

On the one hand, anaerobic digestion offers a local solution for recovering organic waste that would otherwise emit greenhouse gases if left to ferment in the open air. On the other, locally produced biomethane is injected into the gas network for local consumption by companies and individuals located in the vicinity. In addition, the digestate produced is used directly as a natural fertiliser by local farmers.

Bomethane production: how is this sector developing in France and Europe?

France among the leaders in biomethane production in Europe

By 2024, 652 sites in France will be recovering biogas in the form of biomethane, which will be injected into gas networks. 80 of these facilities are connected to the transmission network.

The connected fleet as a whole has a generating capacity of 11 TWh/year. This represents 2.5% of France’s natural gas consumption.

These figures place France among the leaders in biomethane production in Europe. Germany stands alongside France on the podium, producing 12.8 TWh of biomethane a year at 242 sites. The United Kingdom is close on France’s heels, producing 7 TWh per year, followed by Denmark with 5.6 TWh.

This performance in France reflects the French government’s long-standing support for biomethane, which is recognised as one of the keys to achieving France’s energy strategy. As a reminder, the target set by the 2015 Law on Energy Transition for Green Growth (LTECV) is to achieve a production of 39 to 42 TWh by 2030, i.e. 10% of national gas consumption.

Biomethane industry observatory (ODRé site)

GRTgaz’s commitment to the biomethane production sector in France

The production of biomethane injected into networks has accelerated, with a 140% increase in the number of installations between 2020 and 2023.

GRTgaz is contributing to this growth by adapting its transmission system and its offering, and by facilitating connection for producers. Thanks to its knowledge of the network infrastructure and its environment, GRTgaz is raising the awareness of, and informing and mobilising, potential project developers. Alongside its partners, the company supports the maintenance of a tariff framework favourable to the development of the industry.

The MD Biogaz unit at Bar-sur-Seine and the Gazteam Energie unit at Combrand in Deux-Sèvres are among the country’s oldest biomethane production sites connected to the GRTgaz network. This site produces 7,680 m³ of biomethane per day – equivalent to the energy consumption of 4,800 homes.

Innovating with reverse flow stations

Reverse flow stations are designed to capture biomethane produced in excess in a given area, and to transport it to consumption areas further away, and are thus reversing the historical flow of gas. They compress the biomethane in order to transfer the excess production from the downstream distribution network to the upstream transmission network.

After the first installations in 2018 in Noyal-Pontivy (in France’s Morbihan département), and in Pouzauges (based in the Vendée), a whole series of flow station commissioning projects followed on. By the end of 2023, GRTgaz aims to have almost 20 flow station sites up and running with a capacity of 2.4 TWh/year. Commissioned in June 2021, the Marchémoret flow station became GRTgaz’s largest flow station in September 2023, following its extension with a capacity of 6,000 Nm3/hour. GRTgaz is aiming to install 100 flow stations by 2028.

“With reverse flow stations, GRTgaz is demonstrating its ability to keep innovating in order to accommodate as much biomethane as possible in its transmission system. The challenge? Achieving a better match between biomethane production and gas consumption with the aim of optimising energy and avoiding losses.”Gaëlle Eouzan

Biomethane Project Director