Understanding hydrothermal gasification: 5 points

Hydrothermal Gasification recovers organic waste and residues in a very complete manner, offering attractive economic gains.

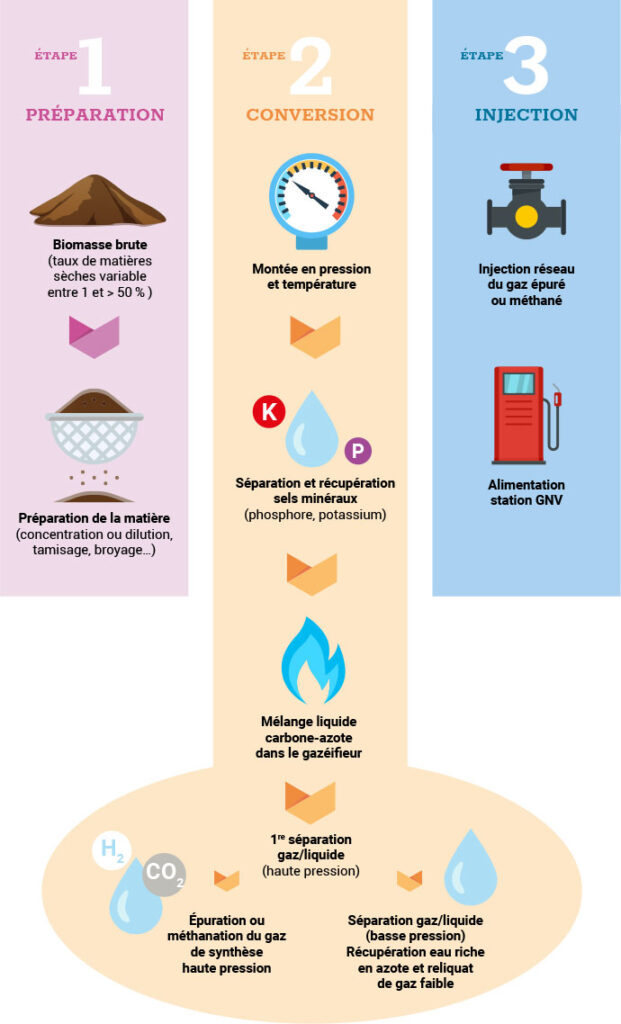

How does Hydrothermal Gasification work?

This high-pressure (210-300 bar), high-temperature (360-700°C) thermochemical process converts wet biomass into synthetic gas: a mixture composed mainly of CH4 (methane), H2 (hydrogen) and CO2 (carbon dioxide).

What are its main features and benefits?

Hydrothermal gasification produces a synthetic gas rich in methane, hydrogen and carbon dioxide. Its composition varies according to the characteristics of the processed biomass, the process employed (with or without integrated catalysis) and the operational functions (flow rate, processing time, presence or absence of a salt separator).

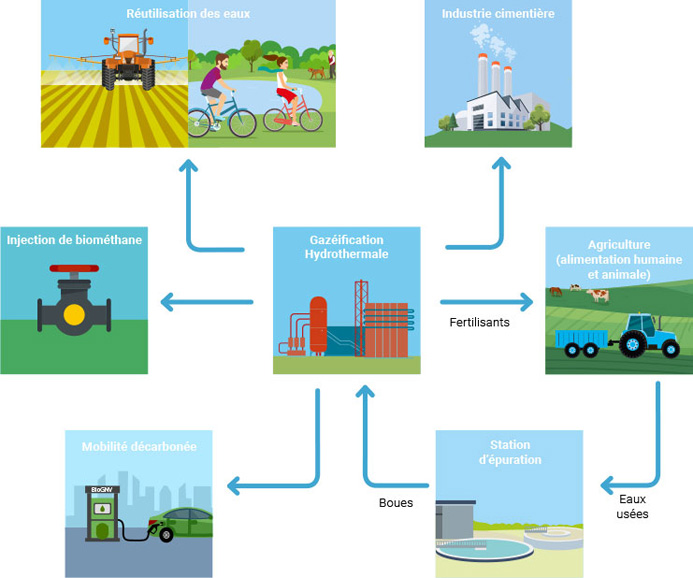

How does hydrothermal gasification fit into the circular economy?

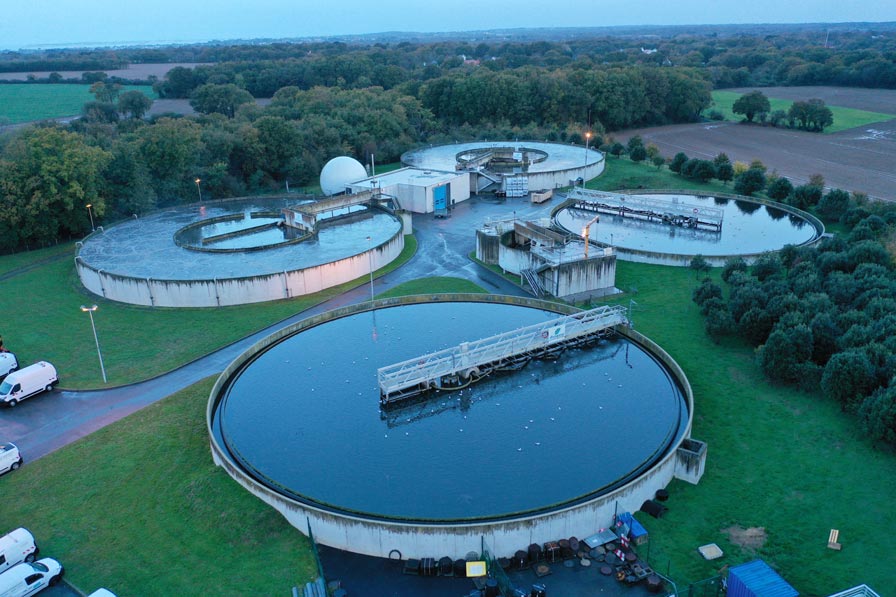

Hydrothermal gasification recovers wet waste and residues as renewable gas, fertilisers and water. This technology greatly reduces the amount of final waste. It has great potential for growing the circular economy, as illustrated by the following diagram showing the recovery of sewage sludge.

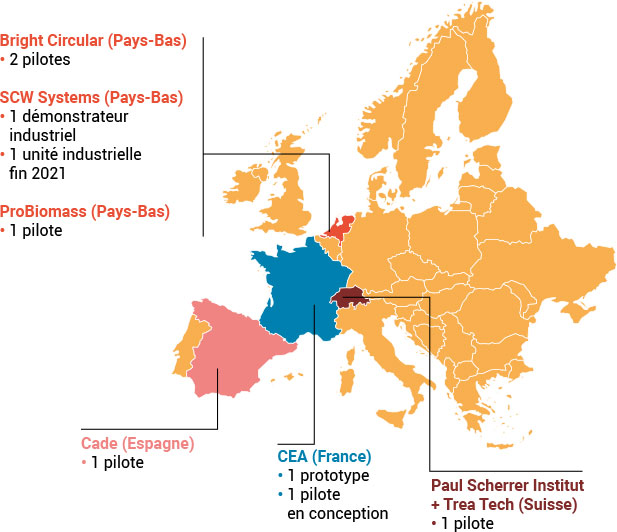

Where are Europe’s most advanced pilot and demonstrator projects located?

Several European stakeholders are developing or operating hydrothermal gasification pilots or demonstrators.

When will we see the first projects in France?

- By 2024/2025

Pilot projects /demonstrators - From 2025/2026

First industrial projects - 20302030 Industrial projects with a cumulative production capacity of at least 1 TWh