White Paper on hydrothermal gasification

As part of the work conducted by the National Hydrothermal Gasification Working Group (HG WG), this White Paper – unveiled at the BIO360 Expo – takes stock for the first time of the progress made thus far with the technology and the sector at European level. The publication also includes an overview of organic waste targeted in France, together with an estimate of gas production potential for 2030 (≥ 2 TWh/year) and 2050 (≥ 50 TWh/year). All this information fosters the emergence of a fully-fledged industrial sector in France based on this disruptive technology. And the first major industrial projects are expected to be operational in 2026.

The main lessons learned from the White Paper

- Hydrothermal gasification is looked at from both a technological and an environmental perspective. It is viewed as a high-performance tool for processing and converting waste into low-carbon renewable gas. It can also be used to recover inorganic compounds (nitrogen, minerals and metals) and water for subsequent conversion.

- The process can be used to convert a wide variety of organic waste – on its own or mixed with other waste that is polluted to varying degrees, mainly of biomass origin, but also of fossil origin. This waste can be found across all regions in the manufacturing, tertiary and farming sectors.

- The array of projects and the maturity of the technology vary from country to country and the developers in question. Some are still at the prototype stage, others are already working with preindustrial pilots or industrial demonstrators. The most advanced player is in the Netherlands and is in the process of launching its first industrial project capable of converting 120,000 tonnes of waste per year.

- This highly innovative but relatively unknown technology is of interest to major waste recycling groups, as well as manufacturers, local authorities and even farmers seeking to optimise their waste recovery processes while keeping the cost down.

- Furthermore, the technology is consistent with a model integrating the circular economy, short distribution channels and decarbonisation. It has numerous benefits and positive externalities, some of which can most likely be monetised in the future for the various public and private stakeholders involved, across all regions.

However, developers of the technology and pioneering players operating in the hydrothermal gasification sector will only be able to flourish if:

- they have access to specific subsidies to finance the R&D initiatives vital for developing the technology so they can protect their investment capabilities and catch up with their foreign competitors;

- they have access to integrated support schemes that are appropriate for the hydrothermal gasification sector (testing contracts like the Dutch SDE++ system) in the 2023 review of the French energy-climate strategy covering both the launch period and the long-term development of this new sector in France.

Towards an extended organic waste processing and recovery capacity

Hydrothermal gasification can be used to convert a wide array of organic waste of biogenic origin into low-carbon renewable gas. This waste can be generated by numerous activities in a range of sectors:

- industrial (agri-foods, paper, pharma, chemical, petrochemical, etc.): waste resulting from the processing of beetroot, crops, potatoes, grapes, fruit and vegetables, animals, black liquor, chemical waste, etc.;

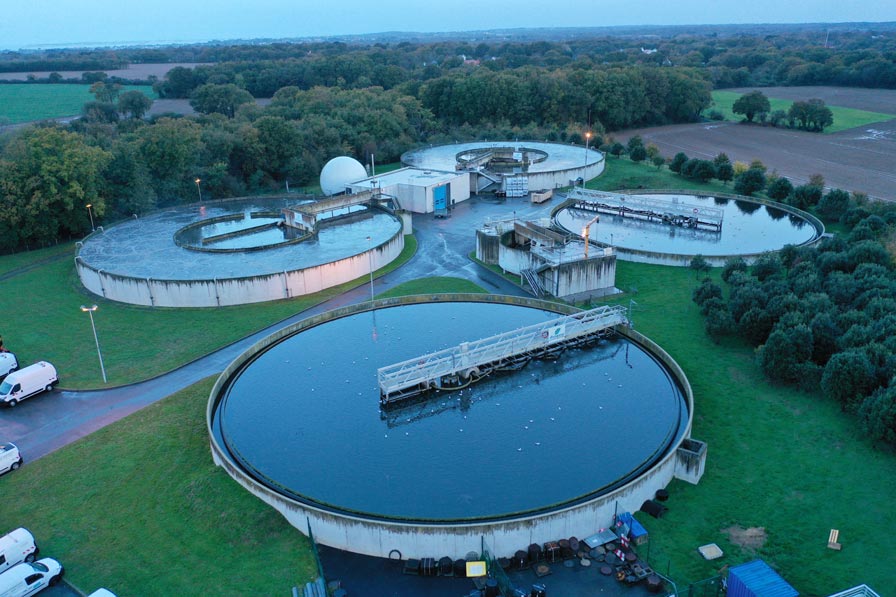

- urban / tertiary: municipal and industrial sludge treatment plants, municipal and tertiary fraction facilities for organic waste with varying levels of pollution and mixed with packaging, dredging and cleaning waste, biowaste;

- farming, including livestock effluent, as well as digestates resulting from methanisation that cannot be spread locally.

It can also be used to convert waste of fossil origin, such as micro plastics, solvents, oils and paints from the chemical and petrochemical industries, as well as fossil-origin waste found in household waste.

The White Paper provides a nationwide inventory of the primary reserves of accessible inputs of "biogenic" origin, a significant part of which can be used for the technology. All of the identified reserves together would result in an estimated 50 TWh GCV of low-carbon renewable gas (at least) being produced per year by 2050.

Currently, a non-negligible share of this waste ends up being incinerated. Some of it is converted into energy, some of it goes to landfill, resulting in pollution risks (air, soil, water) which also need to be managed to limit their impact on the environment.

Hydrothermal gasification enables a more global type of energy conversion – significantly more than other waste recovery technologies. At the same time, the quantity of final waste and atmospheric pollutants is kept to a minimum, or even eliminated altogether.

The National Hydrothermal Gasification Working Group (HG WG) was officially launched in March 2021 at GRTgaz's initiative. As of early 2023, it comprised around fifty economic stakeholders and professional organisations, all driven by shared interests in the energy transition, decarbonisation and the circular economy to benefit the country’s regions.

The Hydrothermal Gasification White Paper is available on request.

Publications

Hydrothermal gasification

Press contacts

Pour aller plus loin

Hydrothermal gasification